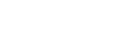

UV Sterilized Electronic Dryer, Welcome to Contact Customer Service

2022-11-15

Sterilization and dehumidification electronic dryer: It is applicable to the daily drying and dehumidification of all kinds of small electronic products (such as hearing aids, wireless headphones, etc.), accessories, etc., and sterilizes. The electronic drying box is used to dry moisture by converting electric energy into heat energy. The drying effect is stronger than that of the drying box. In terms of drying capacity, the electronic dryer has better and more thorough drying effect.

The daily maintenance of hearing aids is very important. It is suggested that the hearing aid should be dried (3-8 hours) every day after use (such as before sleeping) to remove moisture from the hearing aid, so as to carry out daily maintenance and prolong its service life. At the same time, people wear hearing aids every day. When hearing aids contact with the skin, they should keep them clean to prevent bacteria from affecting the human body. Therefore, hearing aids should also be sterilized and treated with UV light. The service life of the hearing aid is prolonged. The utility model reduces the use cost of the hearing aid. It is a good protector of hearing aids.

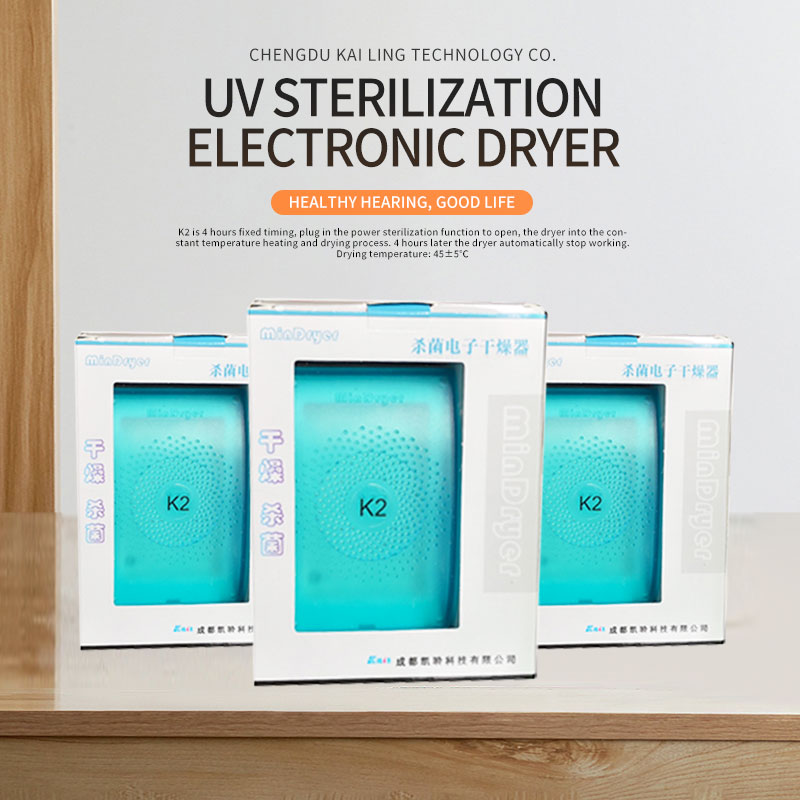

K series sterilizing electronic dryer: the shell is made of flame-retardant ABS material, and the heat source is 45 ± 5 ℃ thermostatic PTC heating plate. The aluminum plate with high heat conductivity is used to evenly transfer the heat energy to the drying chamber to evenly dry small electronic products such as hearing aids. The heating chamber is equipped with two LED UV sterilization lamps, which can sterilize dry objects such as hearing aids while drying.

K series sterilizing electronic dryer: mini in shape, simple, light in weight, 156g, easy to carry, easy to use at home and travel. The buckle structure is adopted for convenient maintenance.

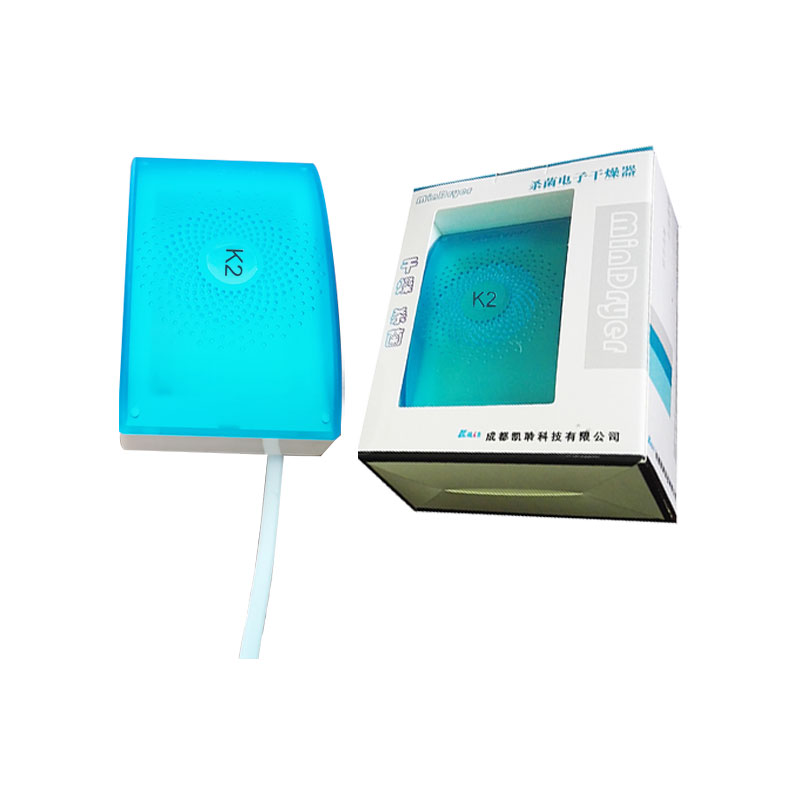

Three models meet different requirements:

K1: dry sterilization, irregular, 45 ± 5 ℃.

K2: drying and sterilization, timed for 4 hours, automatically stopped after working for 4 hours, 45 ± 5 ℃.

K3: sterilization, deodorization, dehumidification and drying. Built in powerful fan, dehumidification and deodorization, intelligent timing function. Drying temperature: 45 ± 5 ℃.

Chengdu Kalen Technology Co., Ltd., founded in 2004, is a one-stop system integration supplier specializing in providing hearing accessories, and one of the earliest professional hearing aid consumables suppliers in China. At present, it has provided services to more than 3000 hearing aid dealers nationwide and some foreign customers. The company integrates the upstream and downstream industrial chain of hearing aids, covering the production, maintenance, hearing detection, fitting and sales of hearing aids to users.

The company has been deeply engaged in the hearing industry for more than 20 years, has profound knowledge of the hearing industry, accumulated rich professional hearing industry product technology and innovation, developed a series of new industrial products, filled the gap of some products in the domestic hearing aid industry, and broke the foreign industry monopoly. A series of hearing aid maintenance and protection products have been introduced to enable users to use hearing aids better and longer.

Kalen Technology has independently developed and produced several kinds of hearing aid production and maintenance equipment and tools, such as a series of ultraviolet light molding machine, wax melting furnace, water pressure pot, polymerized gas pressure pot, special drilling tools for soft ear mold, binaural monitoring earpiece, etc. In terms of hearing detection, we have developed and produced (visual reinforcement audiometry, VRA, behavioral audiometry system, imression syringe, imression taking kit, etc. In terms of hearing aid maintenance, we have developed and produced a series of electronic dryers, a series of hearing aid maintenance instruments (vacuum dehumidifiers), and hearing aid anti loss lanyards.

Contact Person:Luo Jun

Email:188729328@qq.com